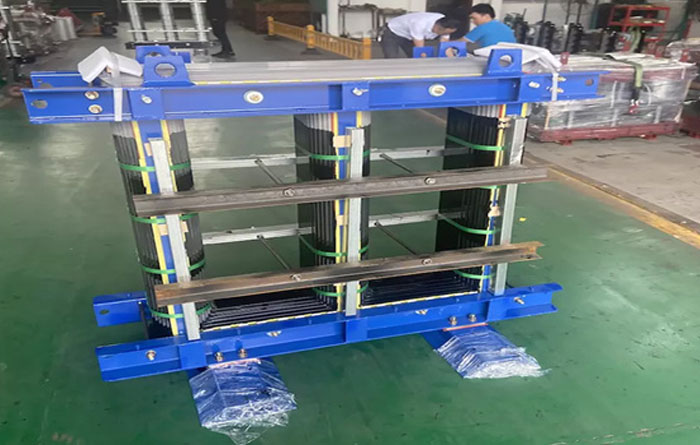

| Model | DKSC-500/20 |

| Low-voltage connection | Y pattern |

| Product drawing number | 5SY.641.500.20.3 |

| Total stack thickness | One hundred and fifty-five millimeters |

| Low-voltage turns | Thirty turns |

| Total weight of iron core | One Thond and seventy-eight kilos |

| Low Voltage | Four hundred volts |

| No-load loss | Less than one thond, one hundred and ninety-five Watts |