Application of Silicon Steel Sheet

The silicon lamination can be used to make core of transformer and motor.

Performance Requirements of Silicon Steel Sheet

The performance requirements of silicon steel are mainly as follows: (1) Low iron loss, which is the most important index of silicon steel sheet quality. Many countries have grades based on iron loss values. The lower the iron loss, the higher the grade. (2) High magnetic induction intensity (magnetic induction) under strong magnetic field, which makes the motor and transformer core volume and weight reduce, saving silicon steel, copper wire and insulation materials. (3) Smooth surface, flat and uniform thickness can improve the core filling coefficient. (4) Good punching is more important for the manufacture of micro, small motor. (5) The surface insulation film has good adhesion and weldability, which can prevent corrosion and improve the punching property. (6) Basically no magnetic aging.

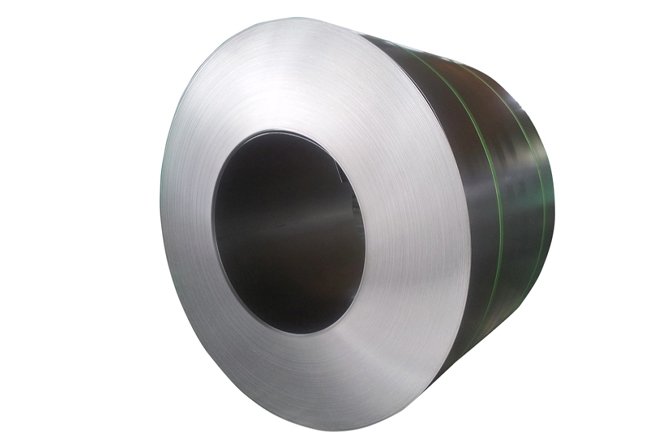

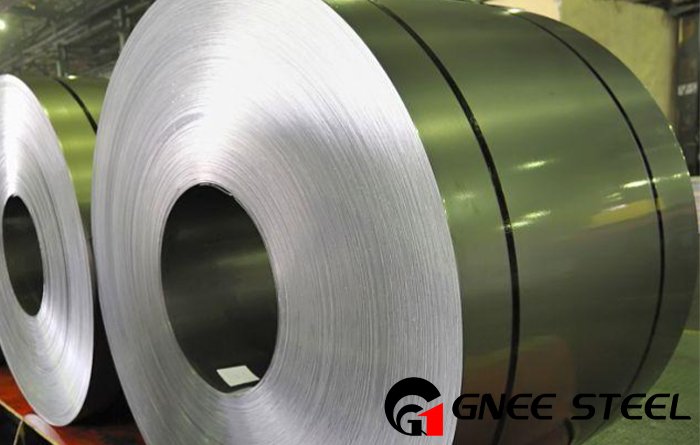

|

Commodity |

|

|

Standard |

JIS/GB |

|

Surface treatment |

Slight oiled |

|

Width |

665mm-1000mm |

|

Thickness |

0.3mm-3mm |

|

Wave Specification |

Depend on the type of the sheet or According to buyer's request |

|

Bundle Weight |

2-3MT |

|

Loading port |

Tianjin, Qingdao, Shanghai and so on. |

|

Package |

Export Sea worthy standard packing |

|

Price terms |

FOB, CFR, CIF |

|

Payment terms |

TT, LC, DP, OA |

|

Application |

motors, generators, alternators, ballasts, small transformers and a variety of other electromagnetic applications. |

|

Delivery time |

20-35 days |

|

Other Remarks |

We deliver by shipping,container or as your requirements. Also we accept the third party inspection. |

Silicon steel sheet cross-cut production line

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)