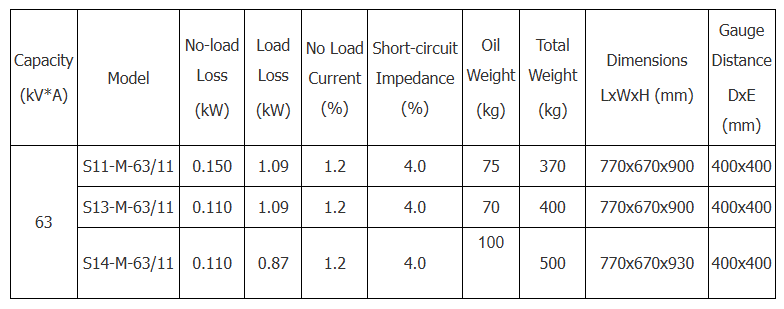

Reliable performance, low loss, and strong short-circuit resistance.

Efficient cooling via corrugated tank. High-grade core and windings ensure durability. Anti-corrosion tank coating extends service life.

Customizable to your needs.

The transformer is engineered using proprietary design tools and software, fully compliant with IEC and Chinese national standards.

The core is built from premium cold-rolled grain-oriented silicon steel, assembled using step-lap technology on a GEORG automatic lamination line.

The tank adopts a corrugated design, produced by GEORG’s advanced fin-forming line. Its surface undergoes international-grade pre-treatment and coating processes, including degreasing, pickling, phosphating, and electrophoresis, followed by high-pressure powder spraying and thermal curing—ensuring exceptional corrosion resistance.

High-voltage windings are made with enamel or paper-insulated wire, while low-voltage coils use a mix of enamel wire, paper-covered wire, and copper strip. This combination ensures optimal turn distribution and a reinforced insulation system, greatly enhancing short-circuit withstand capability.

Moving parts feature a free-hanging core structure, with sealing gaskets made from high-grade acrylic rubber to prevent aging from sunlight and high temperatures.

Email:✉️ sales@gneesteels.com

Phone / WhatsApp: +86 158 2468 7445