1 What is silicon steel?

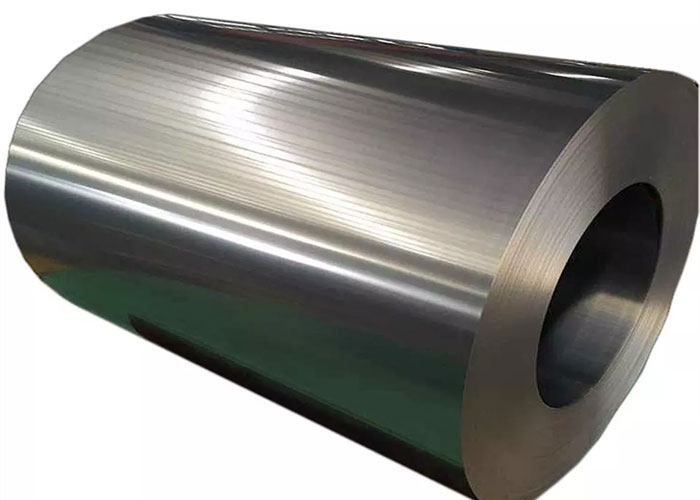

Silicon steel, also known as "electrical steel", is a ferrosilicon soft magnetic alloy with very low carbon content. The addition of silicon can not only increase the resistivity and maximum permeability of iron, but also reduce core loss (iron loss), coercivity, and magnetic aging. It is generally used in the iron core of various motors and transformers, and is an indispensable and important soft magnetic alloy in the electric power, electronics and military industries.

2 Classification of silicon steel

(1) According to the production process: it can be divided into hot-rolled and cold-rolled silicon steel, hot-rolled silicon steel is low utilization, large energy loss, and has been gradually eliminated. Cold-rolled silicon steel is divided into oriented silicon steel and non-oriented silicon steel according to the internal grain orientation.

(2) According to the different silicon content, electrical steel is divided into two types: low silicon wafer (medium and low grade) and high silicon wafer (high grade). Low silicon wafer has a certain mechanical strength, mainly used in the manufacture of motors, commonly known as motor silicon steel sheet; High silicon wafer has good magnetism, but is more brittle, mainly used in the manufacture of transformer core, commonly known as transformer silicon steel sheet.

3 The difference between non-oriented silicon steel and oriented silicon steel

The grains of oriented silicon steel are basically in one direction, with high silicon content, mainly used in transformer manufacturing. Non-oriented silicon steel grain distribution is disorganized, with low silicon content, mainly used in motor manufacturing. The silicon content is generally bounded by 3%; Cold-rolled silicon steel is divided into cold-rolled non-oriented silicon steel and cold-rolled oriented silicon steel.

(1) The production process requirements of cold-rolled non-oriented silicon steel are relatively low, and the silicon quality fraction is between 0.5%-3.0%. The thickness of the finished product made after cold rolling is generally 0.35 and 0.5mm thick steel strip. Its Bs is higher than that of oriented silicon steel, uniform thickness, high dimensional accuracy, smooth and flat surface, and improved filling coefficient and magnetic properties of the material.

(2) The mass fraction of cold-rolled oriented silicon steel silicon is above 3.0%, and the carbon mass fraction is 0.03%-0.05%. Steel has low oxide inclusions and requires inhibitors. Compared with cold-rolled non-oriented silicon steel, oriented silicon steel has lower loss, strong directionality of magnetism, and superior high permeability and low loss characteristics in its rolling direction. Cold-rolled oriented silicon steel, also known as cold-rolled transformer silicon steel, is mainly used in transformer manufacturing.

(3) Cold-rolled oriented silicon steel can also be divided into two categories: ordinary oriented silicon steel (CGO) and high magnetic inductive oriented silicon steel (Hi-B). High magnetic induction cold-rolled oriented silicon steel is single-oriented steel strip, the main use is for the manufacture of various chokes, transformers and other electromagnetic components in electronic instruments.